Our Factory

Who We Are

Established in 2002, we are an all-in-one bag manufacturer for developing and producing custom bags, including a wide range of styles from everyday carry to specialized designs.

We are specialized in creating various types of bags, such as backpacks, tote bags, messenger bags, handbags, duffel bags, and more. Our expertise in bag production ensures high-quality, custom-designed products to suit your specific needs.

Bag Design and Production Specialist

Custom Bag Experts

Your best partner in China.

- More than 21 Years Of Trusted Service

- Over 630+ Brands Coordinated

- Fast Turnaround Time

- Discounts For Large Quantities

- Expert Service & Sales Support

- Money Refund in Case of Poor Quality

Why Choose Majorbags

Majorbags Handbags is a distinguished manufacturer of top-quality handbags, where artistry meets craftsmanship. With state-of-the-art production facilities and a dedicated team of skilled artisans, we take pride in offering an unparalleled range of handbags that combine style, durability, and functionality.

Real Factory

We are a real factory, over 21 years OEM/ODM experience. 15 production lines. 6000 square meters area with more than 200 employees and a 7-member design team.

Craftsmanship at Its Finest

At Majorbags Handbags, we believe in the art of bag-making. Our experienced craftsmen are masters of their trade, meticulously handcrafting each bag with precision and passion. We spare no effort in ensuring that every stitch, every detail, and every design element reflects our commitment to excellence.

Quality You Can Trust

Quality is our cornerstone. We use only the finest materials, carefully selected to guarantee the longevity of our handbags. From genuine leather to durable hardware, our commitment to quality ensures that your LuxCraft handbag is an investment that will stand the test of time.

We Are Trustworthy Bags Manufacturer

We produce the bags everyone needs, from product development to finished product. Working with us, you can just sit back and enjoy our emphasis on innovation, premium quality, fast & stable delivery, fully customized service and sustainability.

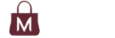

Bag Design

Our bags, a perfect blend of style and practicality. Unique designs, top-notch craftsmanship, accompany you to every occasion. Express your personality, embrace fashion, choose our bags to make life better.

Procurement Supervision

Reliable Procurement Supervision: Your Assurance of Quality and Integrity in Every Purchase.

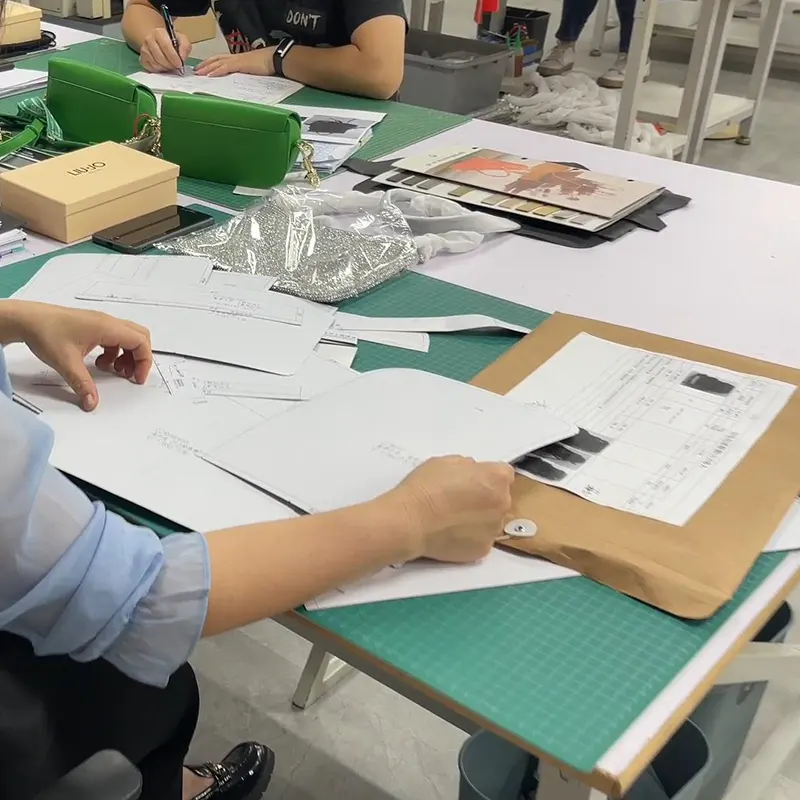

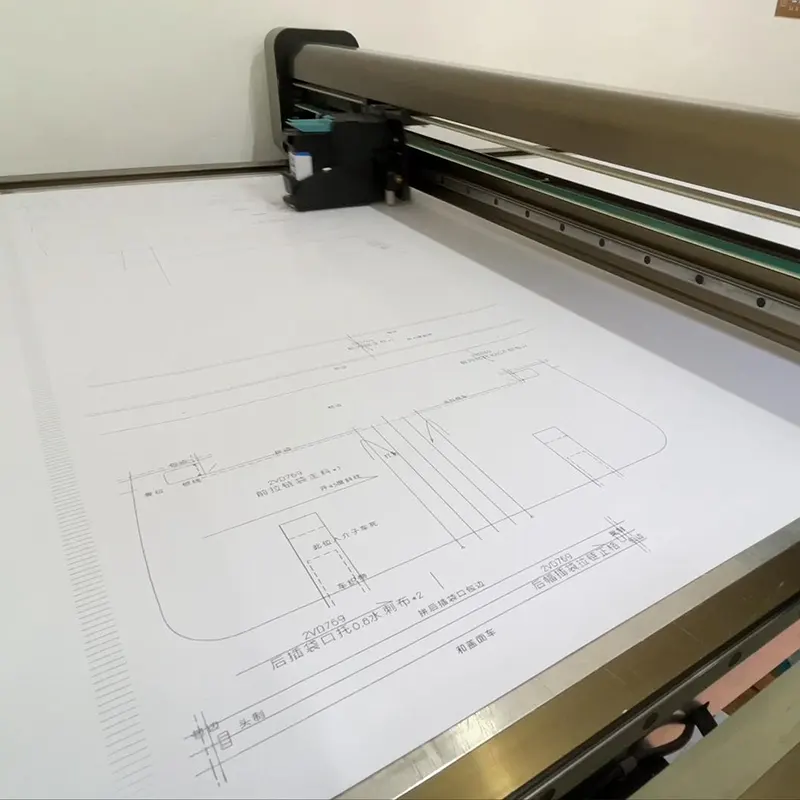

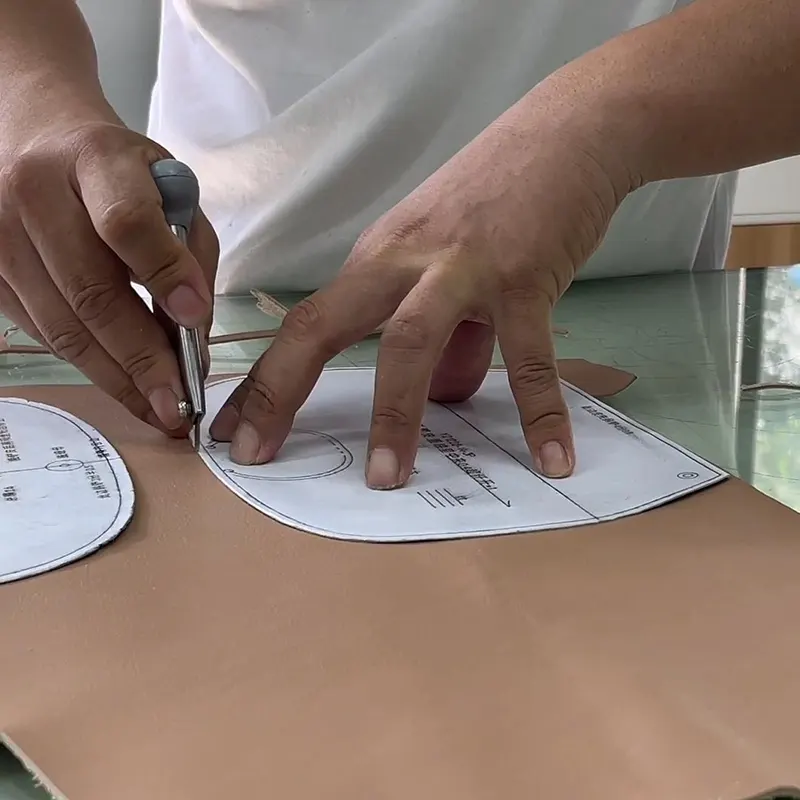

Paper Pattern

Paper Patterns: The Blueprint of Style and Precision, Enhanced by Computer-Aided Design and Automated Printing for Reduced Errors.

Skiving Points

Skiving points play a vital role in bag production, enabling precise cutting while minimizing material waste. These points are strategically chosen to ensure efficient use of resources and achieve accuracy in crafting high-quality bags.

Hand-Cutting Materials

Hand-cutting materials are vital in bag production, demanding precision in measurements and manual cutting for accurate components. This skilled craftsmanship minimizes waste and enhances quality, ensuring each bag is truly exceptional.

Mechanical Cutting

Mechanical cutting is essential in bag production, using precision machinery for accurate and efficient material cutting. This automation minimizes errors, boosts productivity, and yields top-quality bags. It's a critical step in our pursuit of precision and excellence in every bag.

Leather Skiving

Leather skiving is the precise art of thinning and shaping leather for a refined, high-quality bag finish.

Bag Sewing

Sewing is a crucial step in bag production, where skilled artisans meticulously stitch together materials to create durable and stylish bags. Our commitment to craftsmanship ensures quality and precision in every stitch.

Hardware Assembly

Hardware assembly is crucial in bag manufacturing, demanding precision and attention to detail. Our commitment to quality is evident in how we securely and seamlessly integrate zippers, buckles, and metal components, enhancing both aesthetics and functionality.

Sanding and Buffing

Sanding and buffing are essential processes in bag manufacturing. These steps involve refining the surface of the materials, such as leather, to achieve a smooth and polished texture. The attention to detail in sanding and buffing ensures that the bag's finish is not only visually appealing but also comfortable to touch. These processes contribute to the overall quality and aesthetics of the bags we produce.

Edge Dyeing

Edge dyeing is a critical stage in bag manufacturing, where artisans carefully apply a colored dye to the edges of materials like leather. This process not only enhances the bag's overall appearance but also provides protection and durability to the edges, ensuring they maintain their quality and finish over time. Our meticulous edge dyeing process is a testament to our commitment to crafting high-quality bags.

Packaging

Packaging is the final step in bag production, where our products are carefully prepared for delivery. Our attention to detail extends to the packaging process, ensuring that your bags arrive in pristine condition, ready for their journey to you. We take pride in delivering not only exceptional bags but also a complete experience, from production to delivery.

Mass Produce

Mass production in bag manufacturing emphasizes efficiency and precision. We use advanced machinery and streamlined processes to meet high demand. Our unwavering commitment to quality ensures that each bag meets our standards even in large quantities.

Production Workshop

We have multiple workshops and factories, enabling us to fulfill orders on time and in the desired quantity while maintaining quality assurance.

Our Workshops

A short introduction to the workshop instructors and why their background should inspire potential student’s confidence.